Brand Sort:

OMRON

E5AWT-R1KJ Pirce

- Brand: OMRON

- Country: JAPAN

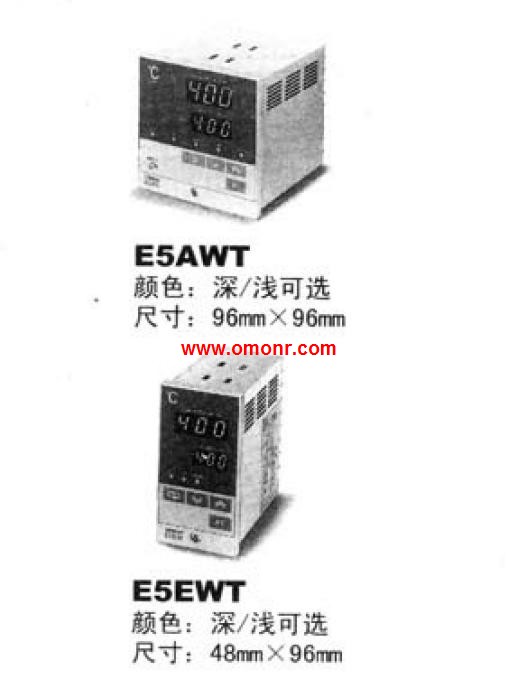

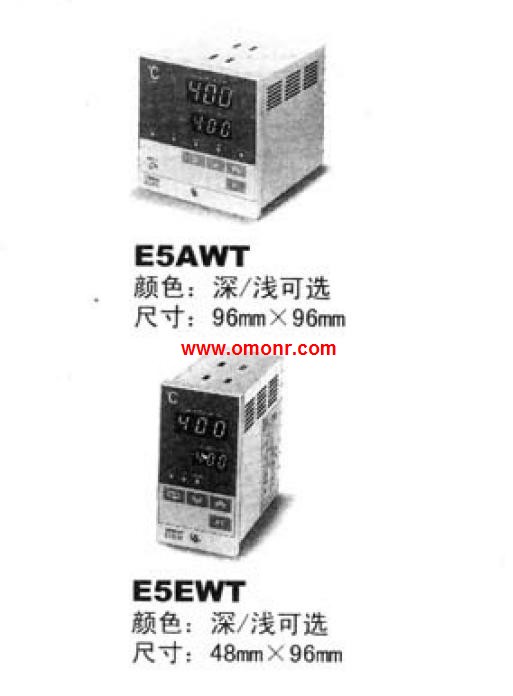

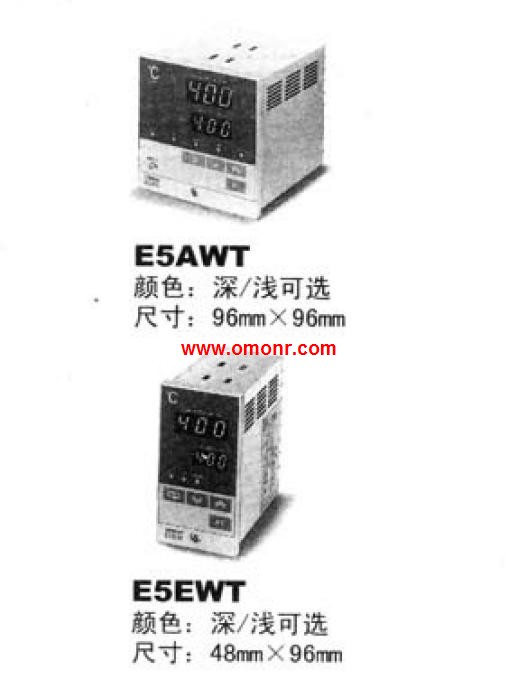

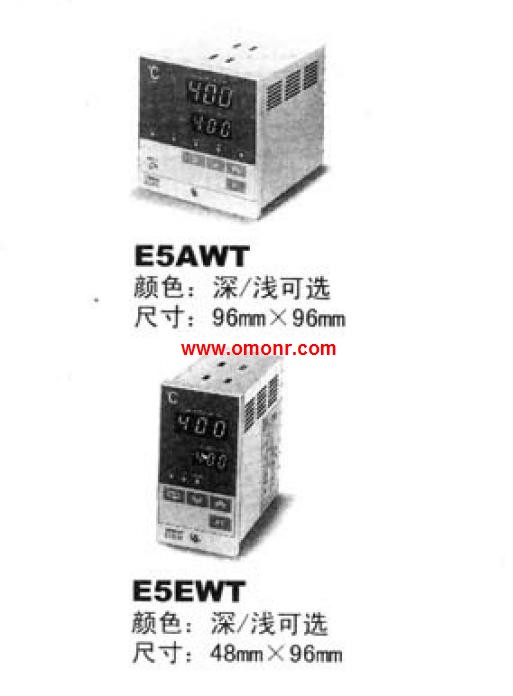

- Name: temperature controller

- Model: E5AWT-R1KJ

- Price: U.S.$ 256.94

OMRON E5AWT-R1KJ

Release Key Type: Standard (metal).

Wiring method: Terminal block.

Solenoid voltage/Indicator: 24VDC (without indicator).

Lock and release type: Solenoid lock Mechanical release.

Contact configuration (door open/closed detection switch,

and lock monitor switch contacts): 4-contact Model,

Insert the built-in switch (A, B, C, D, S, T, U or V) into the blank @.

Conduit size (See Note.): G1/2.

World''s smallest Class 6-contact Guard Lock E5AWT-R1KJ

Safety-door Switch.

.

Wiring time is reduced with two types of wiring.

methods capable of one-touch attachment and removal.

A wide variety of built-in switches can be used for various devices.

(4-, 5-, and 6-contact models are available).

Key holding force of 1,300 N.

It is possible to change the key insertion point.

without detaching the head.

Drive solenoids directly from the Controller.

.

Lockout Key to prevent workers from becoming.

trapped inside the hazardous area.

The vertical D4SL Guard Lock Safety-door Switch,

can be easily mounted on 40 × 40 mm aluminum frames.

The plastic material makes the Slide Key suitable,

for lightweight doors. Appearance: Square/Projection type LED voltage-reduction lighting,

(with Voltage Reduction Unit) A22L-C.

Output: SPST-NO + SPST-NO.

Lighting: LED.

Operating voltage: 100 VAC.

Operation: Alternate operation (self-holding).

Illumination color: R (red); Y (yellow); G (green); W (white); A (blue).

Install in 22-dia. or 25-dia. Panel Cutout.

(When Using a Ring).

Lever for easily mounting and removing the Switch Unit.

Increase wiring efficiency with three-row mounting of Switch Blocks.

Finger protection mechanism on Switch Unit provided as a standard feature.

Use 25-dia. ring to install in 25-dia. panel cutouts.

Mounted using either open-type (fork-type) or closed-type.

(round-type) crimp terminals.

IP65 oil resistance (non-lighted models).

IP65 (lighted models). Unit type: CS1 CPU Bus Unit.

Product Name: MECHATROLINK-II,

compatible Motion Control Unit.

Specifications: Control modes: Position,

speed, or torque control via MECHSTROLINK-II,

Control axes: 32 axes max.

(30 physical axes, 2 virtual axes).

Internal programming language: Special,

motion control language.

No. of unit numbers allocated: 1.

Current consumption: 5V, 0.80A; 26V, --.

Standards: UC1, CE.

Improve Equipment Design Efficiency and,

Shorten Tact Time.

Control Servos for up to 16 axes in a,

motion network with one Position Control,

Unit that supports MECHATROLINK-II .

MECHATROLINK-II is a registered trademark,

of the MECHATROLINK Members Association.

E5AWT-R1KJ Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=E5AWT-R1KJ&select=5

Wiring method: Terminal block.

Solenoid voltage/Indicator: 24VDC (without indicator).

Lock and release type: Solenoid lock Mechanical release.

Contact configuration (door open/closed detection switch,

and lock monitor switch contacts): 4-contact Model,

Insert the built-in switch (A, B, C, D, S, T, U or V) into the blank @.

Conduit size (See Note.): G1/2.

World''s smallest Class 6-contact Guard Lock E5AWT-R1KJ

Safety-door Switch.

Wiring time is reduced with two types of wiring.

methods capable of one-touch attachment and removal.

A wide variety of built-in switches can be used for various devices.

(4-, 5-, and 6-contact models are available).

Key holding force of 1,300 N.

It is possible to change the key insertion point.

without detaching the head.

Drive solenoids directly from the Controller.

Lockout Key to prevent workers from becoming.

trapped inside the hazardous area.

The vertical D4SL Guard Lock Safety-door Switch,

can be easily mounted on 40 × 40 mm aluminum frames.

The plastic material makes the Slide Key suitable,

for lightweight doors. Appearance: Square/Projection type LED voltage-reduction lighting,

(with Voltage Reduction Unit) A22L-C.

Output: SPST-NO + SPST-NO.

Lighting: LED.

Operating voltage: 100 VAC.

Operation: Alternate operation (self-holding).

Illumination color: R (red); Y (yellow); G (green); W (white); A (blue).

Install in 22-dia. or 25-dia. Panel Cutout.

(When Using a Ring).

Lever for easily mounting and removing the Switch Unit.

Increase wiring efficiency with three-row mounting of Switch Blocks.

Finger protection mechanism on Switch Unit provided as a standard feature.

Use 25-dia. ring to install in 25-dia. panel cutouts.

Mounted using either open-type (fork-type) or closed-type.

(round-type) crimp terminals.

IP65 oil resistance (non-lighted models).

IP65 (lighted models). Unit type: CS1 CPU Bus Unit.

Product Name: MECHATROLINK-II,

compatible Motion Control Unit.

Specifications: Control modes: Position,

speed, or torque control via MECHSTROLINK-II,

Control axes: 32 axes max.

(30 physical axes, 2 virtual axes).

Internal programming language: Special,

motion control language.

No. of unit numbers allocated: 1.

Current consumption: 5V, 0.80A; 26V, --.

Standards: UC1, CE.

Improve Equipment Design Efficiency and,

Shorten Tact Time.

Control Servos for up to 16 axes in a,

motion network with one Position Control,

Unit that supports MECHATROLINK-II .

MECHATROLINK-II is a registered trademark,

of the MECHATROLINK Members Association.

E5AWT-R1KJ Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=E5AWT-R1KJ&select=5

...more relevant model market price >>>>

Related products

OMRON

temperature controller

E5AWT-Q1KJ

Size: 96 x 96mm.

Type: thermocouple type

OMRON

temperature controller

E5BWT-R1KJ

Size: 72 x 72mm.

Type: thermocouple type

OMRON

temperature controller

E5AWT-R1P

Size: 96 x 96mm.

Type: Platinum resistan

OMRON

Temperature Controllers

E5CSV-R1KJ-W

Size: E5CSV 48 × 48mm.

Type: Terminal