Brand:

OMRON

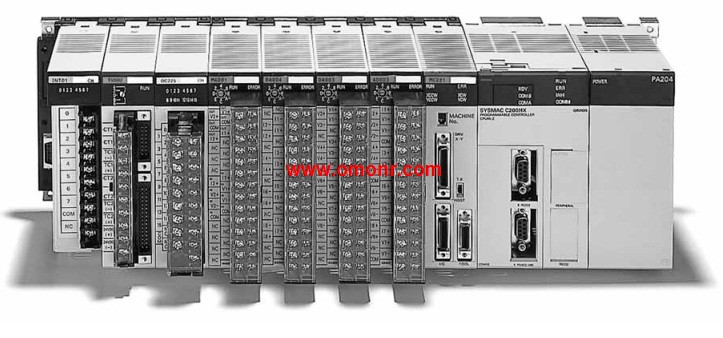

C200H-CN111 | OMRON Power Cable C200H-CN111

OMRON C200H-CN111 Product information and technical parameters:

Brand: OMRON

Name: Power Cable

Model: C200H-CN111

Connects Power Supply Adapter and SYSMAC NET Link Unit.

For 1 Unit.

Model: C200H-ID218.

No. of points: 32 pts.

Specifications: 24 VDC.

Weight: 180g max.UM: 15.2K words.

DM: 6K words.

EM: 6K words.

Instruction processing time (basic instructions): 0.15 µ.s min.

No. of I/O points: 1, 184 points.

Max. no.of con-necting Expansion I/O Racks: 3 Racks.

Max. no. of connecting High-density I/O Units(i OMRON C200H-CN111. e., Group-2): Unavailable.

Max. no. of con-necting Special I/O Units: 10 C200H-CN111

RS-232C: NO.Model: C200H-OC222.

No. of points: 12 pts.

Specifications: 2A, 250VAC/24VDC(For resistive loads).C200H-COVC200H-CPU31-E CPU

High-Performance CIM Version

The C200H-CPU31-E controller offers a high-performance CPU especially designed for computer integrated manufacturing environments OMRON C200H-CN111.

The C200H-CPU31-E has all the capabilities of C200H C200H CPU21/CPU23,

with clock/calendar as a standard feature.This CPU is used in either SYSMAC NET and/or SYSMAC LINK communicationName: CompoBus/S Master Module.

Model: C200HW-SRM21-V1.

Communications protocol: Dedicated CompoBus/S protocol.

CompoBus/S Master Unit

High-speed ON/OFF Bus Saving Wiring Effort and Manufacturing Steps in Factories OMRON C200H-CN111. Name: Motion Control Module .

Model: C200H-MC221.

Number of I/O words: 20 (2 slots).

External connecting devices: IBM PC/AT or compatible, Teaching Box, and MPG (manual pulse generator).

Controlled driver: Servodrivers that can handle analog inputsUM: 31.2K words.

DM: 6K words.

EM: 6Kx3 banks(18K) words.

Instruction processing time (basic instructions): 0.1 µ.s min.

No. of I/O points: 880 points.

Max. no.of con-necting Expansion I/O Racks: 2 Racks.

Max. no. of connecting High-density I/O Units(i.e., Group-2): Unavailable.

Max. no. of con-necting Special I/O Units: 10.

RS-232C: NO.24 VDC.C200H Accessory Interface Unit C200H-IP007Power supply voltage: AC100 ~ 120V, AC200 ~ 240V.

Note: can be switched.

Comply with EU directives.

Can only be used for C200H-CPU series and C200HS-CPU series.

Co creation will be able to track the market speed of the production site.

In order to build a more convenient system for the user and the sales department.

OMRON actively promote the field of information and standardization.

The Windows version of the ladder program as a tool in the windows environment of unity.

In addition to Ethernet, the communication protocol macro function must be provided in accordance with DeviceNet/D.

As a result of this kind of environment is all ready, just realized one call that is out, quickly adapt to the market changes of the production environment.

Improve reliability, strengthen the function to a new generation.

Due to the production site more complex, high speed, the user''s demand is also increasingly diveerse C200H-CN111.

To this end, it is required to improve the basic performance of C200HG/C200HE/C200HX, improve the processing speed and so on.

Production site requirements of high performance, high standards, and constantly upgrading!

The creation of the modern manufacturing industry, the strict requirements of OMRON,

Always take the latest products and scientific concepts to the production site C200H-CN111.

No. of points: 32 pts.

Specifications: 24 VDC.

Weight: 180g max.UM: 15.2K words.

DM: 6K words.

EM: 6K words.

Instruction processing time (basic instructions): 0.15 µ.s min.

No. of I/O points: 1, 184 points.

Max. no.of con-necting Expansion I/O Racks: 3 Racks.

Max. no. of connecting High-density I/O Units(i OMRON C200H-CN111. e., Group-2): Unavailable.

Max. no. of con-necting Special I/O Units: 10 C200H-CN111

RS-232C: NO.Model: C200H-OC222.

No. of points: 12 pts.

Specifications: 2A, 250VAC/24VDC(For resistive loads).C200H-COVC200H-CPU31-E CPU

High-Performance CIM Version

The C200H-CPU31-E controller offers a high-performance CPU especially designed for computer integrated manufacturing environments OMRON C200H-CN111.

The C200H-CPU31-E has all the capabilities of C200H C200H CPU21/CPU23,

with clock/calendar as a standard feature.This CPU is used in either SYSMAC NET and/or SYSMAC LINK communicationName: CompoBus/S Master Module.

Model: C200HW-SRM21-V1.

Communications protocol: Dedicated CompoBus/S protocol.

CompoBus/S Master Unit

High-speed ON/OFF Bus Saving Wiring Effort and Manufacturing Steps in Factories OMRON C200H-CN111. Name: Motion Control Module .

Model: C200H-MC221.

Number of I/O words: 20 (2 slots).

External connecting devices: IBM PC/AT or compatible, Teaching Box, and MPG (manual pulse generator).

Controlled driver: Servodrivers that can handle analog inputsUM: 31.2K words.

DM: 6K words.

EM: 6Kx3 banks(18K) words.

Instruction processing time (basic instructions): 0.1 µ.s min.

No. of I/O points: 880 points.

Max. no.of con-necting Expansion I/O Racks: 2 Racks.

Max. no. of connecting High-density I/O Units(i.e., Group-2): Unavailable.

Max. no. of con-necting Special I/O Units: 10.

RS-232C: NO.24 VDC.C200H Accessory Interface Unit C200H-IP007Power supply voltage: AC100 ~ 120V, AC200 ~ 240V.

Note: can be switched.

Comply with EU directives.

Can only be used for C200H-CPU series and C200HS-CPU series.

Co creation will be able to track the market speed of the production site.

In order to build a more convenient system for the user and the sales department.

OMRON actively promote the field of information and standardization.

The Windows version of the ladder program as a tool in the windows environment of unity.

In addition to Ethernet, the communication protocol macro function must be provided in accordance with DeviceNet/D.

As a result of this kind of environment is all ready, just realized one call that is out, quickly adapt to the market changes of the production environment.

Improve reliability, strengthen the function to a new generation.

Due to the production site more complex, high speed, the user''s demand is also increasingly diveerse C200H-CN111.

To this end, it is required to improve the basic performance of C200HG/C200HE/C200HX, improve the processing speed and so on.

Production site requirements of high performance, high standards, and constantly upgrading!

The creation of the modern manufacturing industry, the strict requirements of OMRON,

Always take the latest products and scientific concepts to the production site C200H-CN111.

...More relevant models >>>>